Butt-welded Fittings

-

Monel 400 Fittings

Monel alloy has comprehensive properties of strong toughness and corrosion resistance, and is widely used in chemical and other industries. For example, for the manufacture of heaters, heat exchangers, evaporators, distillation kettles, distillation towers, fatty acid treatment condensers, processing Rosin Pavilion acid equipment, chemical pumps, etc.

Email Details

Because the Monel alloy also has high strength and good oxidation resistance at high temperature, it can also be used in heat treatment industry to manufacture all kinds of structural parts. In the nuclear power industry, the alloy has good corrosion resistance to high temperature and high pressure water, so it is also an important structural material for light water reactor nuclear power plant. The products are plate, rod, wire, strip and pipe. -

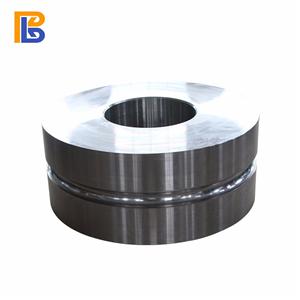

ASME B16.9 Standard Butt Welded Fittings

We supply ASME B16.9 Standard Butt Welded Fittings, which mainly with carbon steels, stainless steels, alloy steels and others.

Email Details

And which are used in the fields of petroleum, chemical, shipbuilding, metallurgy, electricity and mechanical industries; and we regularly cooperate with petrol-chemical plants, shipyards and boiler shops.

For ASME B16.9 Standard Butt Welded Fittings, we have very rich exporting experience to Europe, US, North America and Asia with more than 10 years.

We have very strict quality control system from raw materials to final proudcts according to ISO9001. meanwhile we have approved certificates of API, TUV, PED and some Classification society qualification. -

C276 Nickel Based Alloys Fittings

Nickel-based alloy is a kind of alloy which has high strength and anti-oxidation corrosion ability at 650 ℃ and 1000 ℃. We supply C276 nickel based alloys fittings, which mainly with C276, Incoloy800, Incoloy800H, and Incoloy825 series. And which are used in the fields of ocean, environmental, protection, energy, petrochemical and food.

Email Details

It has high strength and anti-oxidation corrosion capacity at 650 ℃ and 1000 ℃. Because of its high enough high temperature strength and anti-oxidation corrosion ability, it is often used to manufacture aero-engine blades and rocket engines and nuclear reactors. High temperature components on Energy conversion equipments. -

S31803 Duplex Fittings

S31803 duplex fittings have good welding performance, compared with ferrite stainless steel and austenitic stainless steel fittings. it is not like the welding heat-affected zone of ferrite stainless steel, and the plasticity and toughness are greatly reduced due to severe grain coarsening. Nor is it as sensitive to welding thermal cracks as austenitic stainless steel.

Email Details

Due to its special advantages, S31803 duplex fittings have been widely used in petrochemical equipment, seawater and wastewater treatment equipment, oil and gas pipelines, paper-making machinery and other industrial fields. In recent years, it has also been used in the field of bridge load-bearing structure.

It has a good prospect of development. Duplex stainless steel is composed of half ferrite phase and austenite phase in the quenched microstructure, and the content of the minimum phase may be up to 30%. -

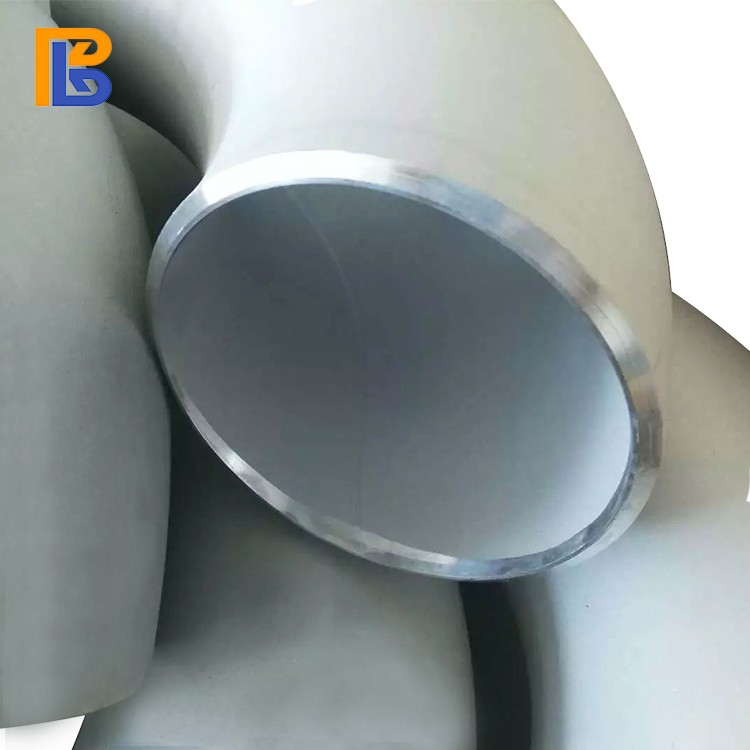

180 Degree Return Bends

180 degree return bends require very high demand for production process. From raw materials, manufacturing technology, to finished products.

Email Details

Do well products trace-ability is one of the key points for 180 degree return bends. We do PMI test from raw materials to final products, so, the labeled transplantation is very important.

Nondestructive examination (NDE) need carry out on each piece of the 180 degree steel elbows. Depends on the materials, we need do Magnetic particle test, Penetration test, Ultrasonic test, Radio graphic test, and any other as customers' requirements. -

180 Degree Steel Elbows

For 180 degree steel elbows, which mainly with carbon steels, stainless steels, alloy steels and some special materials, such as 2205, C276, Monel 400 series.

Email Details

180 degree steel elbows are mainly used in the fields of petroleum, chemical, shipbuilding, metallurgy, electricity and mechanical industries.

We have very mature manufacturing technology, from the choice of raw-material specification to the well control of the medium frequency temperature, so we can make sure the wall thickness within your requirements, especially for the back wall thickness.