Machined Parts

-

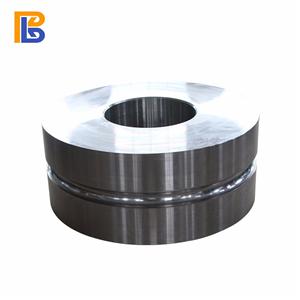

Machining Service For Semi-finished Forgings

Machining Service For Semi-finished Forgings

Machining Service For Semi-finished Forgings can do according to clients's requirement.Machining Service For Semi-finished Forgings can do groove,hole,thread ,etc through turning ,miling,CNC machiningMachining Service For Semi-finished Forgings customized mechanical components machinery forging componentsEmail Details -

Customized Machined Parts

Customized Machined Parts:

Email Details

we can customized machined parts according to clients's requirement. And the machined parts have excellent flatness, verticality, straightness, degree of symmetry, smooth finish. -

Customized Mechanical Components

Turning Machined Parts:

Email Details

we can customized mechanical components according to clients's requirement. And the machined parts have excellent flatness ,verticality ,straightness ,degree of symmetry ,smooth finish -

Turning Machined Parts

turning metal parts,Higher accuracy ,stable quality . Turning machined parts ,in generally ,there are two steps , rough turning and finished turning . The purpose of rough turning cut the vast majority machining allowances of machining surface . During rough turning ,there is not the strict requirement for the machining surface ,just keep some machining allowances for semi-finished and finished turning . Rought turning also can find the defect of the inner ,and can dispel the residual stress and thermal deofrmation.Finished machining make sure the tolerance and the surface quality.

Email Details -

Milling Machined Parts

milling machinery parts have many character ,for example ,excellent flatness ,verticality , straightness ,degree of symmetry ,smooth finish .Milling Machined Parts Can mill the surface(horizontal , vertical , ) ,groove( key groove , T type groove , dovetail groove , etc ) , slip tooth parts (gear , spline shaft , sprocket wheel ) , spiral surface (thread ,thread groove ) ,etc. Milling Machined Parts Can also machine complex shaped profile , the efficiency is higher , widely used to machinery manufacture . Milling Machined Parts Can do millling , lead plug , bore a hole .

Email Details -

Machined Castings Parts

Machining of Castings casting parts require some finishing of the details. Some casting methods (such as melt casting and die casting) are more precise than other casting methods, but there are always some dimensional tolerances or Geometry cannot be cast directly and must be machined. Usually OEMs or other end users provide castings to the machine shop, which are finished by the machine shop and then returned to the OEM.

Email Details

Usually, some processing shops specialize in the finishing of castings. However, some workshops are reluctant to process the castings because the smoke generated by the machining of the castings will be drilled into certain parts of the machining tool, thereby accelerating tool wear and reducing tool accuracy. -

Finished Machined Flanges

Finished Machined Flanges can do according to clients's requirement.

Email Details

Finished Machined Flanges can do groove,hole,thread ,etc through turning ,miling,CNC machining -

CNC Machining Parts

CNC Machining Parts: more complex construction ,many parts to difficult to control size ,like mold parts,shell parts . According to the CNC specical ,it is suitable many condition products. For example,1. Many kinds of products,and the small quantity parts or new products sample.2. Complex shape,high machining accuracy , high accuracy of manufacture , universal machine tool can’t machine or can’t make sure the quality.3. Numerical value of the surface roughness is small .4. The complex outline shape parts . ...

Email Details -

Chemical Industry Mechanical Components

Chemical Industry Mechanical Components:

Email Details

There are many types and specifications of chemical equipment parts, different process requirements, and different structural shapes. Chemical Industry Mechanical Components can be divided into two categories, one is general-purpose parts, and the other is common parts of various typical chemical equipment. In order to facilitate the design, a repair is made, and the structural shapes of these components are unified into several specifications, and they are common to each other and become common components.

Parts that meet the standard specifications are called standard parts.