Hot Forgings

-

Open Die Forgings

Boberry's open die forgings are produced based on end customers' technical drawings. Open die forgings include different kinds of shapes for different applications.

Email Details

Certification: ISO9001, PED ,SGS etc. Material Report for Open Die Forgings: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report.

Open Die Forgings Process: Raw material inspection →Cutting→ inspection → Preheat → forging → heat treatment → inspection → rough machining → NDT →Testing → finishing machining →NDT →inspection → packing→ Delivery. -

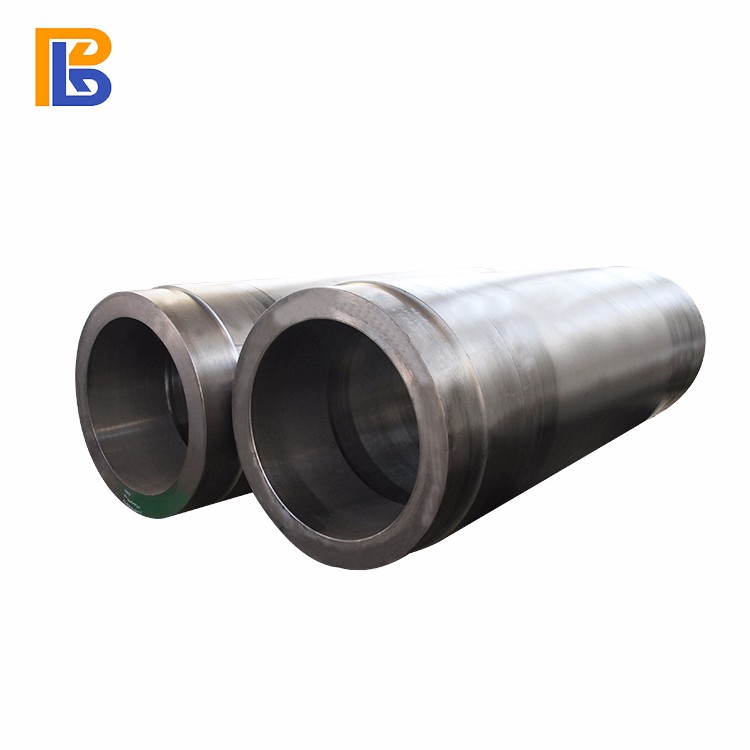

Different Application Sleeves

Different Application Sleeves

Email Details

Process: forging+ heating treatment+machining (other process can be customized)

Material: Alloy steel, Carbon steel, Stainless steel etc.

Finish: Plain, Nickel Plating, Chrome Plating, Polishing. -

Wind Turbines Motor Shafts

Boberry produces Wind Turbines Motor Shafts with dimensional uniformity. And we can produce Wind Turbines Motor Shafts according to customer's drawings.

Email Details

Main material for Wind Turbines Motor Shafts covers carbon steel, alloy steel, stainless steel and nickel alloys etc.

Certification: ISO9001, PED ,SGS etc. Material Report for Wind Turbines Motor Shafts: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report. -

Hot

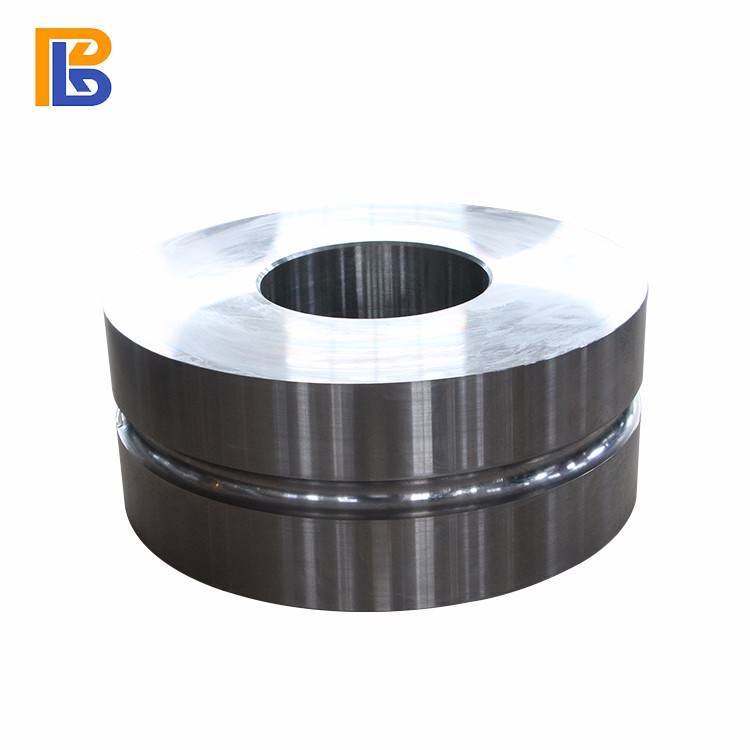

Steel Forged Sleeves

Steel Forged Sleeves

Email Details

1. Boberry manufactures steel forged sleeves for different industrial applications.

2. Size: customer drawings and requirement.

3. Standard: GB,JIS.

4. Certification: ISO9001, PED ,SGS. -

Blind Hole Cylinders

Blind hole cylinders are forged based on your forging drawing. Main material covers carbon steel, alloy steel, stainless steel and nickel alloys etc.

Email Details

Blind hole cylinders are used for different applications, such as steel bushing, casing cover. They are ultrasonically tested according to the applicable ASTM, AMS, ASME, NACE, SAE, AISI or other standards.

Certification: ISO9001, PED ,SGS etc. Material Report for Blind Hole Cylinders: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report. -

Forged Steel Hollow

Forged Steel Hollow Application: Automotive, Mining, Railway, Crane industry, Port machine, Construction etc.

Email Details

Forged Steel Hollow Quality Control: Flaw detection, Inspection, Stress measurement, Hardness tester, Spectrometre,Tensile tester, Sensors etc. -

Hot Forged Cylinder Parts

Boberry produces Hot Forged Cylinder Parts based on your forging drawing. Main material covers carbon steel, alloy steel, stainless steel and nickel alloys etc.

Email Details

Hot Forged Cylinder Parts Standard: ASTM, DIN, CE, EN, ISO, BS, UL, GS, BV.

Hot Forged Cylinder Parts Package detail: Fumigation wooden case, wooden pallet or iron box etc. -

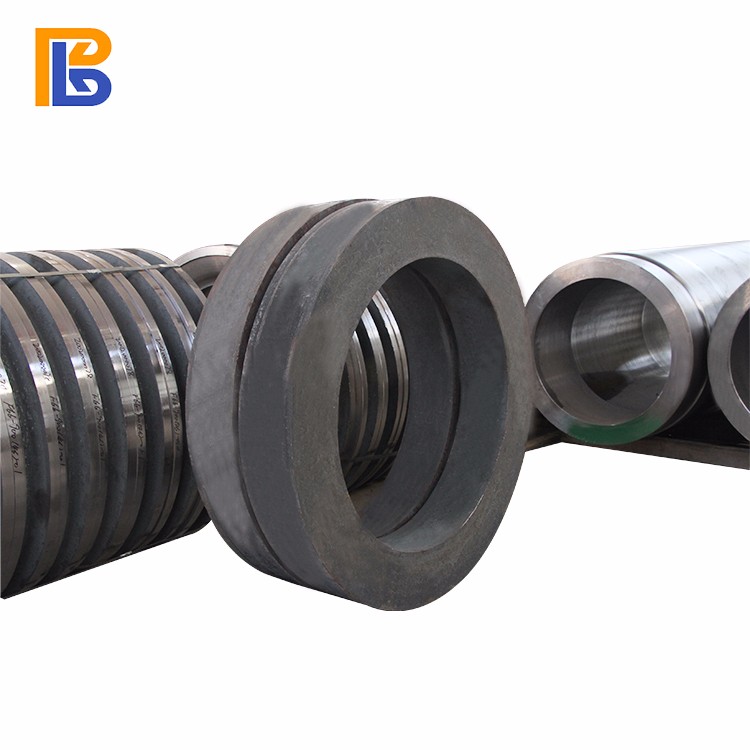

Forged Mill Wheel

Forged Mill Wheel series: wheel for railway passenger coach, for railway freight wagon, for locomotive, for metro car, for light rail vehicle.

Email Details

Forged Mill Wheel characters: High tolerance, High tensile strength, Optimum performance, Heavy Load support. -

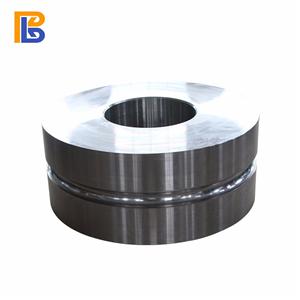

Forged Steel Hub For Coupling

Forged Steel Hub For Coupling Processing equipment: CNC lathe, CNC milling machine, machining center

Email Details

Forged Steel Hub For Coupling Packaging Details: Wooden case or as per client requirement

Forged Steel Hub For Coupling Delivery Time: Delivery 15-30 days after payment