Standard Flanges

-

Standard Pressure Vessel Flanges

Model NO.: The Standard pressure vessel flanges

Email Details

Type: Welding Flange

Structure: Round

Sealing Surface: RF

Shape: Circle

Material Grade: 304,316L,321,347H etc.

Specification: TUV, ISO9001, BV, TS, CCS

HS Code: 7307210000 -

Ring Type Joint Flange

Ring type joint flanges are used to ensure leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flange.

Email Details -

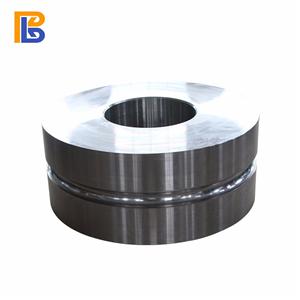

Lap Joint Flanges

The lap joint flange is a kind of steel part, which is often used as a connection change. The product standard is GB/T 9120-2010.

Email Details

Flange can be divided into five basic types according to the way of connection with the pipe: flat welding flange, welding flange, thread flange, socket welding flange, lap joint flange. There are many types of sealing faces for flanges. Commonly used are face (RF), concave (FM), convex (M), face (T), groove (G), full plane (FF), ring connection. Face (RJ).

The lap joint flange is actually equivalent to the combination of two flanges. -

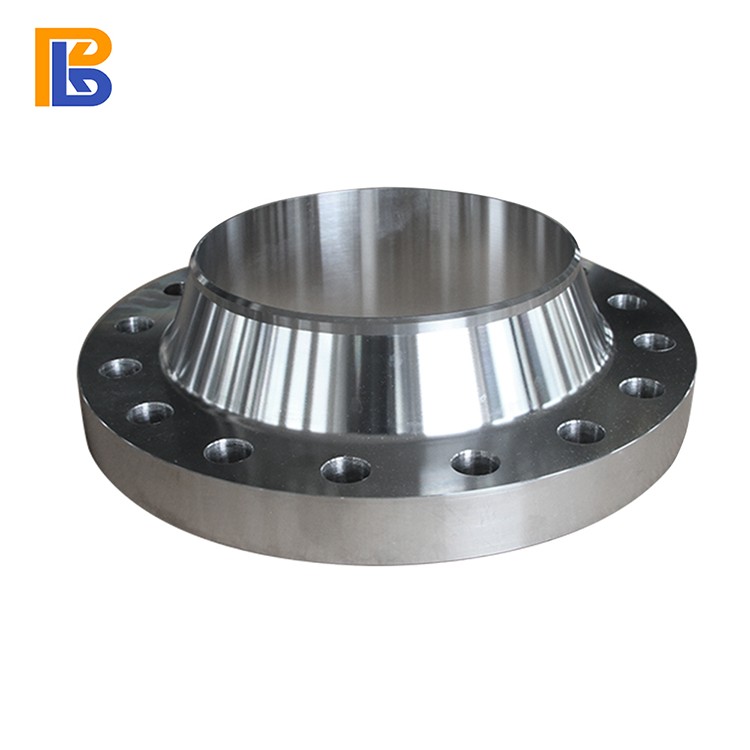

Weld Neck Flanges

1. Name: Weld Neck Flange

Email Details

2. Process Type: Forged

3. Material: Stainless Steel (f316/f316l)

4. Size Range: 1/2"-72"

5. Pressure: Ansi150lb-2500lb

A weld neck flange is a type of pipe and refers to a flange with a neck that has a transition of a round pipe and is butt welded to the pipe. The weld neck flange is not easy to be deformed, sealed well, widely used, has corresponding rigidity and elasticity requirements and reasonable butt welding thinning transition, the welding joint is away from the joint surface, and the joint surface is protected from welding temperature deformation. -

Threaded Flanges

A threaded flange is a type of flange that is threaded to the pipe. Designed with a loose flange. The advantage is that no welding is required and the additional torque generated on the cylinder or pipe when the flange is deformed is small. The disadvantage of threaded flanges is that the flange is thick and the cost is high. Suitable for connection to high pressure pipes.

Email Details

Threaded flanges are made by machining the inner bore of the flange into a pipe thread and connecting it with a threaded pipe. The threaded flange is a non-welded flange. Compared with the flat welding flange or the butt welding flange, the threaded flange has the characteristics of convenient installation and maintenance, and can be used on some pipelines where welding is not allowed on the site. Alloy steel flanges have sufficient strength, but are not easy to weld, or the welding performance is not good, and the threaded flange can also be selected.

However, it is recommended not to use a threaded flange to avoid leakage when the temperature of the pipe changes sharply or the temperature is higher than 260 °C and lower than -45 °C. -

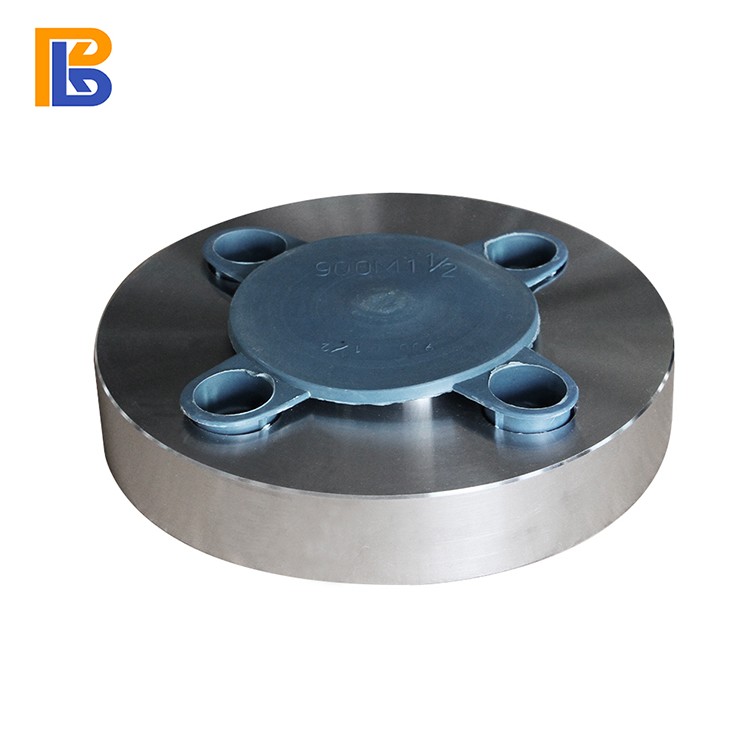

Blind Flanges

The blind flange is a flange without a hole in the middle for sealing the pipe plug. There are many types of sealing surfaces, such as planes, convex surfaces, concave and convex surfaces, grooved surfaces, and ring joint surfaces.

Email Details

The blind flanges production process is mainly divided into three types: forging, casting, and cutting. -

Socket Weld Flanges

The socket weld flange refers to a flange that is inserted into the flange ring step at the end of the pipe and welded at the pipe end and the outside.

Email Details

There are two types of neck and no neck. The neck flange has good rigidity, small welding deformation and good sealing performance, and can be used for the pressure of 1.0~10.0MPa. The B-flange for containers is also a socket weld flange for applications where sealing requirements are high.

When designing, the socket weld flange can be checked by integral flange. -

Slip On Flanges

The slip on flange is a movable flange. It is usually matched on the water supply and drainage fittings (the most common is on the expansion joint),which is directly related to the pipeline and equipment in the project connected by bolts.

Email Details

The slip on flange is suitable for the connection of non-ferrous metals,such as steel,aluminum,stainless acid-resistant steel containers and corrosion-resistant pipelines.

Meanwhile,the slip on flange is generally used on pipes, in which case the bolts can be rotated to rotate the pipes on both sides and then tightened. It is convenient to disassemble the pipeline. -

Standard Flanges

Standard flanges:

Email Details

The national standard flange connection is to fix two pipes, pipe fittings or equipment on a flange, and between the two flanges, with flange pads, bolted together, completed connection. Some fittings and equipment have their own flanges and are also flanged.

Flange connection is an important connection method for pipeline construction. The flange connection is easy to use and can withstand large pressures. Flange connections are widely used in industrial piping. In the home, the pipe diameter is small and low pressure, and the flange connection is not visible. If you are in a boiler room or production site, there are flanged pipes and equipment everywhere.

According to the connection type of flange connection can be divided into: integral pipe flange, steel pipe flange,threaded flange, slip-on welding flange,socket welding flange,lap joint flange,welding neckflange,blind flange,welding neck collar,etc.