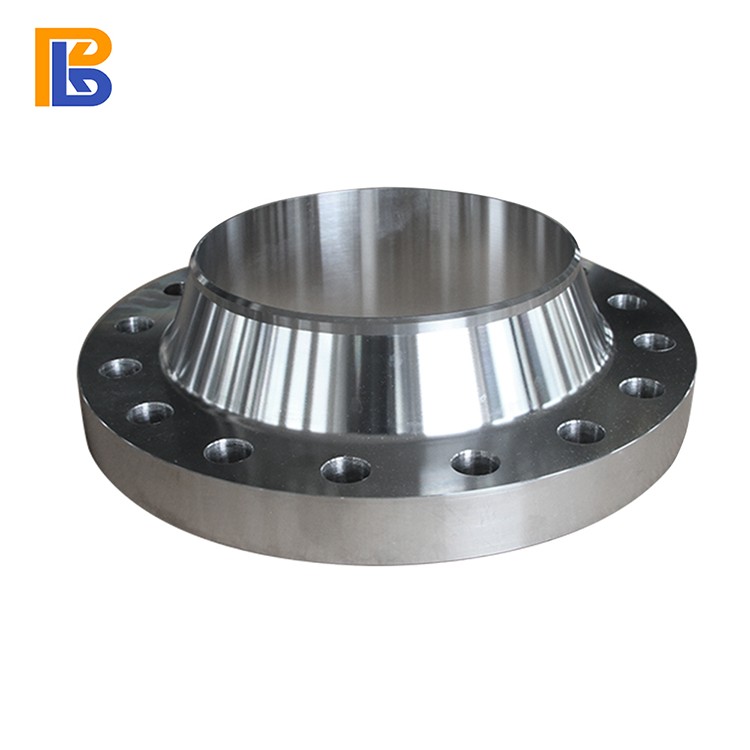

Blind Flanges

- BOBERRY

- China

- 15-30 Days

- 150-200Tons/month

The blind flange is a flange without a hole in the middle for sealing the pipe plug. There are many types of sealing surfaces, such as planes, convex surfaces, concave and convex surfaces, grooved surfaces, and ring joint surfaces.

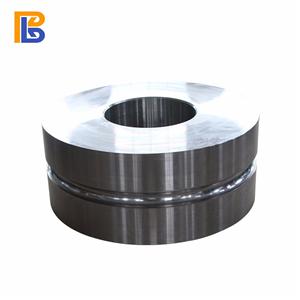

The blind flanges production process is mainly divided into three types: forging, casting, and cutting.

The blind flange serves as the isolation and cutting function, and the function of the head and as the same usage of the cap. Due to its good sealing performance, it is generally a reliable means of isolation for systems that require complete isolation. A blind flange is a solid circle with a handle that is used in a system that is normally isolated. When the normal operation is required, the throttle ring end is used, and the installation gap of the blind plate on the pipeline can also be filled. Another feature is that the logo is obvious and easy to identify the installation status.

One of its functions is to block the end of the pipe, and the second is to have the function of removing the debris in the pipe during maintenance. As far as the sealing is concerned, it has the same effect as the head and the cap. However, there is no way to remove the head, and the blind flange plate is bolted and easy to disassemble. our blind flanges are made of carbon steel, alloy steel, stainless steel, etc.

Stainless Steel DIN2527 Blind Flange as following:

1. Size: 15mm-6000mm

2. Type: Blind

3. Standard: ANSI B16.5, DIN, JIS, GOST, BS, EN and so on

4. Material: A182 F304/304L, F316/316L, 317, 321, 310s, 316ti, 316H.317H.317L. 904L, 321H,347H, 310H, UNS31803, UNS32750, UNS32760.

5. Class: 150#-2500#

We can also supply WN flanges, SO flanges, SW flanges, Threaded flange and so on.

6. Surface:

ANTI-RUST OIL OR PAINTING

7. 8" and bellow size will packed by plywood case.

10" and above size will packed by plywood pallet

8. Usage: Petroleum industry, Refinery Company, fertilizer industry, power station, shipbuilding, onshore platform

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more