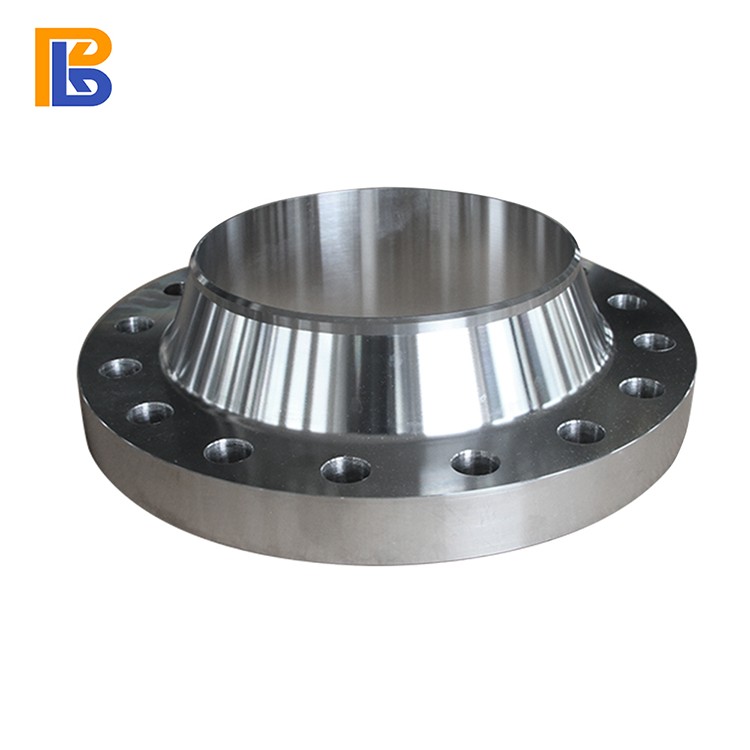

Weld Neck Flanges

- BOBERRY

- China

- 15-30 Days

- 150-200 Tons/month

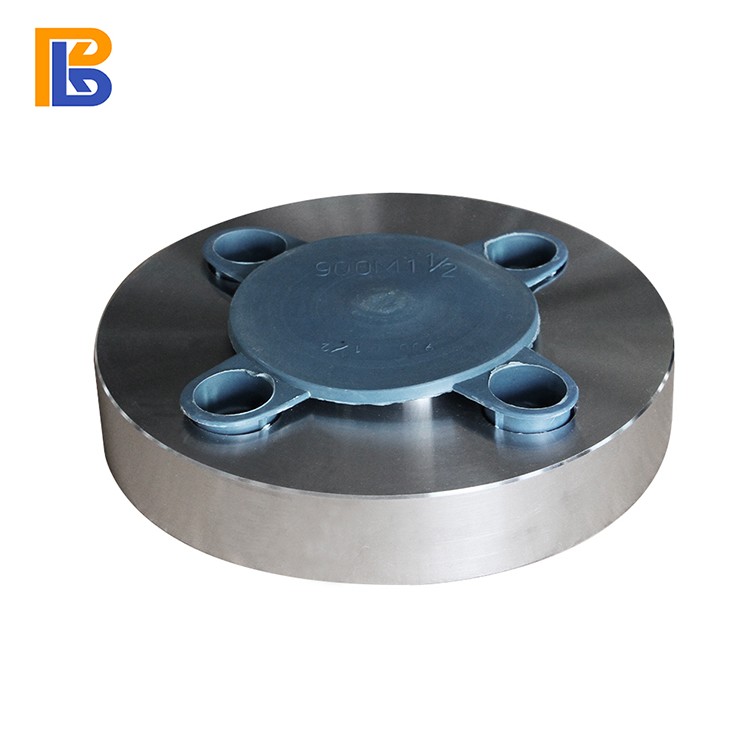

1. Name: Weld Neck Flange

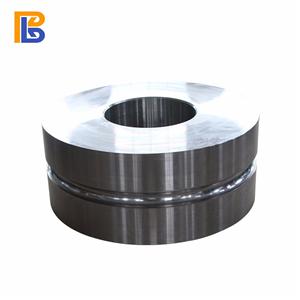

2. Process Type: Forged

3. Material: Stainless Steel (f316/f316l)

4. Size Range: 1/2"-72"

5. Pressure: Ansi150lb-2500lb

A weld neck flange is a type of pipe and refers to a flange with a neck that has a transition of a round pipe and is butt welded to the pipe. The weld neck flange is not easy to be deformed, sealed well, widely used, has corresponding rigidity and elasticity requirements and reasonable butt welding thinning transition, the welding joint is away from the joint surface, and the joint surface is protected from welding temperature deformation.

Usage:

The weld neck flange is not easy to be deformed, sealed, widely used, has corresponding rigidity and elasticity requirements and reasonable butt welding thinning transition, the welding joint is away from the joint surface, the joint surface is protected from welding temperature deformation, it takes more complicated It is suitable for pipelines with high pressure or temperature fluctuations or pipelines with high temperature, high pressure and low temperature. The weld neck flange is generally used for the connection of pipelines and valves with PN greater than 2.5MPa. It is also used for shipping the expensive, flammable and explosive tube.

Process:

Connection form Single-sided welding, double-sided nut connection.

Product features Beautiful appearance, smooth surface, acid and alkali resistance, anti-corrosion, strong texture performance.

The weld neck flanges Production process Iotope furnace cutting, integral forging or finished forging cutting.

Machining method High-precision CNC lathe turning, CNC rocker drilling.

Product parameters

(1) Bolt hole center circle diameter: 50mm----2130mm

(2) Bolt hole diameter: 11mm-30mm

(3) Flange thickness: 12mm-58mm

(4) Pipe outer diameter: A (17. 2-2032MM) B (14-2020MM)

(5) Flange inner diameter: A (18-2036MM) B (15-2024MM)

(6) Flange theoretical weight: 0.36kg--234.6kg (DN1800)

First, the level of the welding flange and its technical requirements should meet the corresponding requirements of JB4726-4728.

1.Grade I forgings are allowed for carbon steel and austenitic stainless steel forgings with a nominal pressure PN of 0.25MP-1.0MPa.

2. Except for the following provisions, forgings with nominal pressure PN of 1.6MPa-6.3MPa shall meet the requirements of Grade II or above forgings.

3. One of the following conditions shall meet the requirements of III and forgings:

(1) Forgings for flanges with nominal pressure PN≥10.0MPa;

(2) Forgings for chrome-molybdenum steel with nominal pressure PN>4.0MPa;

(3) Ferritic steel forgings with a pressure PN > 1.6 MPa and an operating temperature ≤ -20 °C.

Second, the weld neck flange is generally made of forging or forging process. When using steel plate or section steel, it must meet the following requirements:

1.The welding flange should be ultrasonically inspected without delamination defects;

2. It should be cut into strips along the rolling direction of the steel, and welded into a ring by bending. And the surface of the steel is formed into a cylindrical cylinder. The steel plate shall not be directly machined into a neck weld flange;

3. The butt weld of the ring shall be fully penetration welded;

4. The butt weld of the ring shall be post-weld heat treated and 100% ray or Ultrasonic flaw detection, and the radiographic inspection meets the Class II requirements of JB4730, and the ultrasonic flaw detection meets the Class I requirements of JB4730.

Third, the outer side of the neck of the welded flange should be no more than 7o. The welding flange is strictly controlled in the production and welding to ensure that it can fully play its role and value in production and use.

Standard:

| Standard | Size | Pressure | Type | |

| EN | EN1092-1 | DN10-DN600 | PN16-PN100 | PL BL WN SO LAP SW TH |

| ANSI | ANSI B16.5 | DN10-DN600 | 150LBS ~ 3000LBS | PL BL WN SO LAP SW TH |

| ANSI B16.47 | DN10-DN600 | 150LBS ~ 3000LBS | PL BL WN SO LAP SW TH | |

| JIS | JIS B2220 | DN10-DN600 | 5K-40K | PL,BL |

| DIN | DIN 2573,2576 | DN10-DN600 | PN6 | SO |

| DIN 2543,2544 | DN10-DN600 | PN16 | SO | |

| DIN 2527 | DN10-DN600 | PN6-PN100 | BL | |

| DIN 2541,2542 | DN10-DN600 | PN6,PN10 | LAP | |

| DIN 2501,2502,2503 | DN10-DN600 | PN16,PN25,PN40 | SO | |

| BS | BS 4504 | DN10-DN600 | PN10,PN40 | SO,BL |

| BS10 TABLE - D / E / F | DN10-DN600 | - | SO, LAP | |

| GOST | GOST 12820-80 | DN10-DN600 | PN6-PN25 | SO,BL |

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more