Threaded Flanges

- BOBERRY

- China

- 20-35 Days

- 150-200 Tons/Month

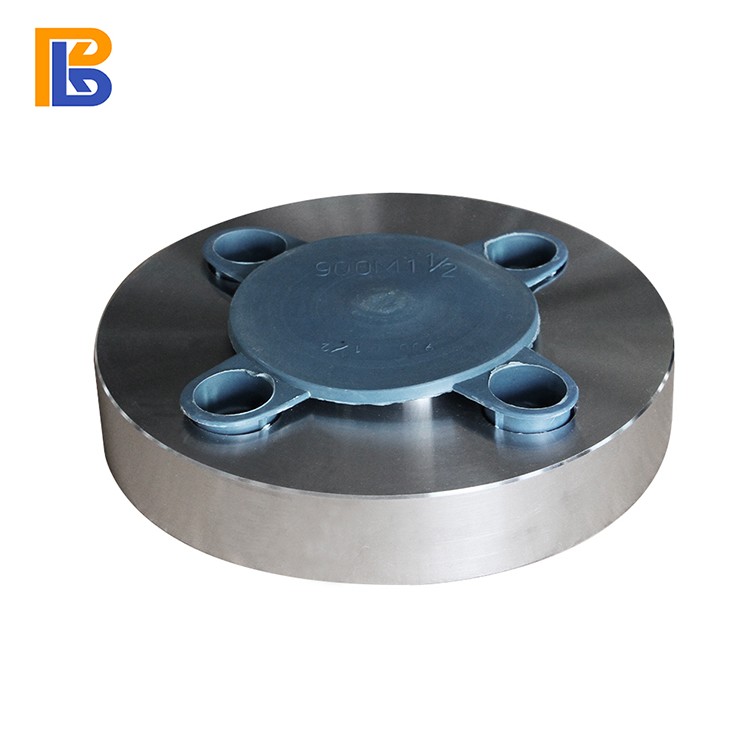

A threaded flange is a type of flange that is threaded to the pipe. Designed with a loose flange. The advantage is that no welding is required and the additional torque generated on the cylinder or pipe when the flange is deformed is small. The disadvantage of threaded flanges is that the flange is thick and the cost is high. Suitable for connection to high pressure pipes.

Threaded flanges are made by machining the inner bore of the flange into a pipe thread and connecting it with a threaded pipe. The threaded flange is a non-welded flange. Compared with the flat welding flange or the butt welding flange, the threaded flange has the characteristics of convenient installation and maintenance, and can be used on some pipelines where welding is not allowed on the site. Alloy steel flanges have sufficient strength, but are not easy to weld, or the welding performance is not good, and the threaded flange can also be selected.

However, it is recommended not to use a threaded flange to avoid leakage when the temperature of the pipe changes sharply or the temperature is higher than 260 °C and lower than -45 °C.

Thread flanges

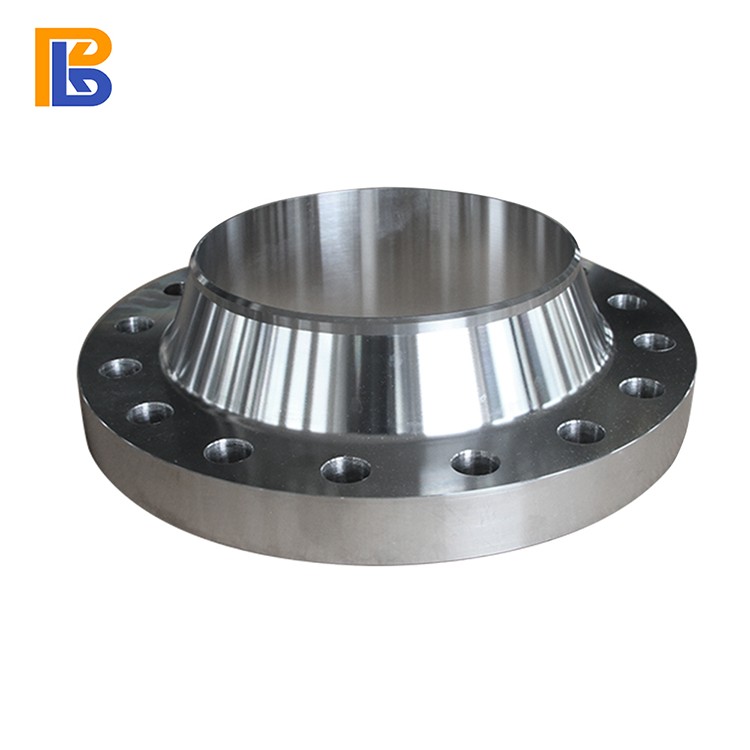

1. Size: 15mm-600mm

2. Type: Threaded

3. Standard: ANSI B16.5, DIN, JIS, GOST, BS, En and so on

4. Material: F304/F304L/304H/F316/F316L/316H/316Ti/F321/321H/317/317L/347/F347H/310S/254Mo/s32750/904L/S31803/2205/F51/F53/inconel600/inconel625/incoloy 800/incoloy800H/ incoloy 525/C-276/Monel400/alloy 20

5. Class: 150#-2500#

6. Our main clients are from Turkey, Italy, France, Germany and so on

7. Usage: Petroleum industry, Refinery Company, fertilizer industry, power station, shipbuilding, onshore platform

| Materials | Carbon Steel: ASTM A105. ASTM A350 LF1. LF2, CL1/CL2, A234, S235JRG2, P245GH and so on |

| P250GH, P280GHM 16MN, 20MN ,20# | |

| Stainless Steel: ASTM A182, F304/304L, F316/316L and so on | |

| Alloy Steel: A182 F11, A182F22, A182F12, A182 F5, A182F91, A182 F9 and so on | |

| Types | Slip On Plate Flange/Plate Flange , Slip On Hub Flange/Bossed |

| Welding Neck Flange/WN flange/ Loose Flange/Lapped Flange /Backing Flange | |

| Blind Flange/Blank flange, Lap Joint Flange /LJ Flange | |

| Socket Weld Flange/SW Flange Threaded Flange/Screwed Flange | |

| Loose Flange/Lapped Flange Backing Flange RTJ /o-Ring | |

| Custom Flange/Special Flange Hot/Cold/Electro Gavanized Flange | |

| Standards | ANSI/ASME/ASA B16.5 Flanges, ANSI B16.47 A/B Flanges |

| JIS B 2220 FLANGES, KS B 1503, DIN SERIES, UNI, EN1092-1, BS4504 | |

| BS 10 TABLE D/E/F Flanges, SANS 1123 Flanges/SABS 1123 | |

| GOST12820-80/GOST12821-80, NFE29203/NS/AS/ISO/AWWA Flanges | |

| Pressure &Ratings | 150LBS, 300,600,900,1500,2500 ANSI, ASA B16.5 |

| PN6 PN10 PN16 PN25 PN40 PN64-DIN/UNI | |

| PN6 PN10 PN16 PN25 PN40 PN63-EN1092-1/BS4504 | |

| PN0.6Pa, PN1.0Pa, PN1.6. PN2.5,PN4.0-GOST12820-80 | |

| PN0.6Pa, PN1.0Pa, PN1.6. PN2.5,PN4.0, PN6.3. -GOST12821-80 | |

| 600kPa, 1000.1600.2500.4000.-SANS 1123 | |

| 5KG, 10KG, 16KG, 20KG, 30KG, 40KG-JIS B2220/KS B1503 | |

| TABLE D, TABLE E ,TABLE F-BS 10, AS2129 | |

| CLASS D, CLASS E, CALSS F, AWWA C207 | |

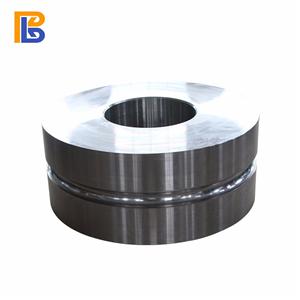

| Surface Treatment | Rust Prevention , Black Paint Coating or Phosphating Treatment with Black Color |

| Varnish Paint Coating, Varnish Oil Coating, | |

| Electro Galvanizing Coating (Cold Galvanizing, Color Golden or silvery white, Coating thickness 20~30μm) | |

| Hot Dip Galvanizing Coating (Coating Thickness 200μm around) | |

| Technical | Forging |

| Application | Water works, Shipbuilding industry, Petrochemical & Gas industry, Power industry, Valve industry |

| and general pipes connecting projects etc. | |

| Inspection | Quality Control System-Well Equipments and Machinery-Well Workers and Engineers |

| Packing | Wooden Pallets or Wooden Cases or As Customers' Requirements |

| Payment Terms | L/C Or 30 % Advance By T/T and The balance Will be Paid After the copy of B/L |

| Delivery Time | 30 Days \after the Advance or the L/C |

| After-Sales Service | Orders and Products Tracking System |

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more