Hot Forgings

-

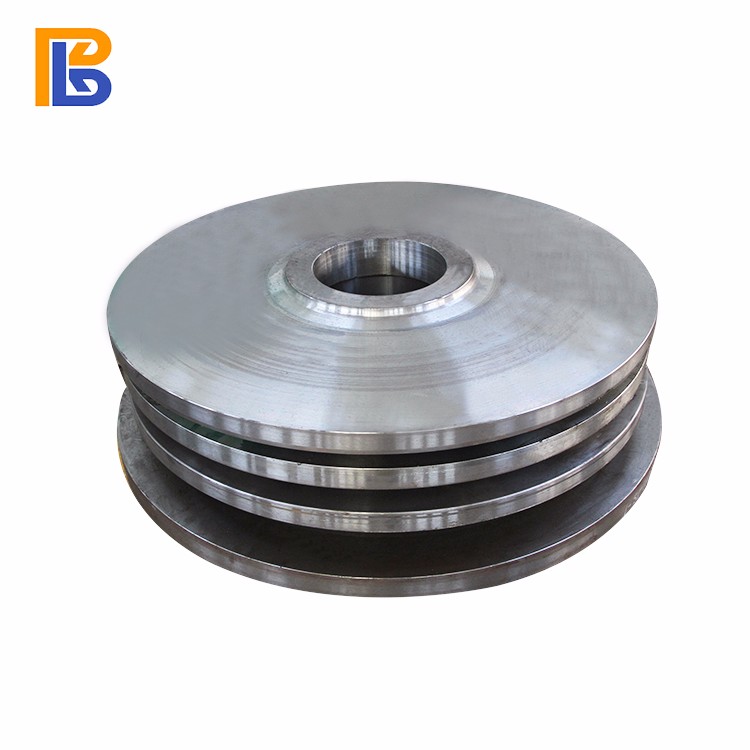

Hub To Shaft Connector

Hub To Shaft Connector International standard clamp power locks, keyless locking device, Adjustable Locking Device, Safe Locking Device, Precesion High Power Transmission Power Lock, Keyless shaft Locking Device, joint shaft axle wheel, auto universal joint, cross joint.

Email Details -

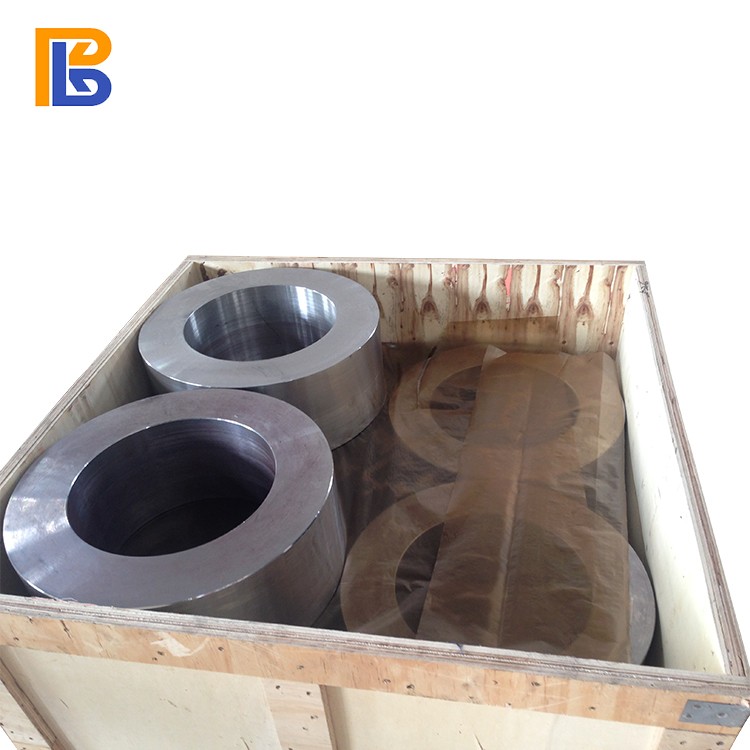

Forged Discs

Forged Discs Main Application: Vessel, Heavy Industry Equipment, Infrastructure

Email Details

Forged Discs Material: Carbon Steel, Stainless Steel, Corrosion Resistant Alloys, Super Alloys, Special Stainless Steel, Die Steel, Structural Alloy Steel -

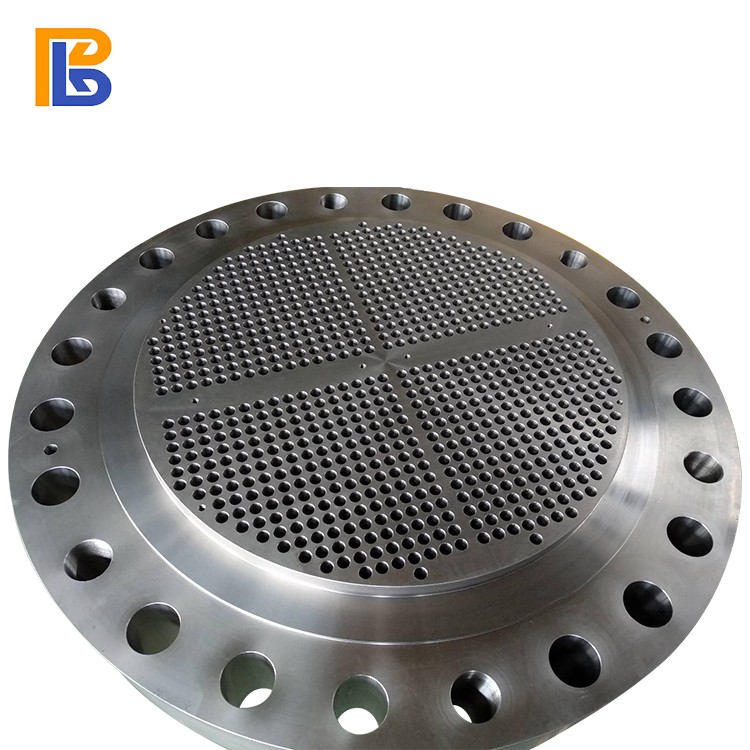

Tube Sheets

Forged tube sheets for heat exchanger.

Email Details

Tube Sheets Material: Carbon Steel, Stainless Steel, Corrosion Resistant Alloys, Super Alloys, Special Stainless Steel, Die Steel, Structural Alloy Steel.

Tube Sheets Drilling and machining as customer's requirement. -

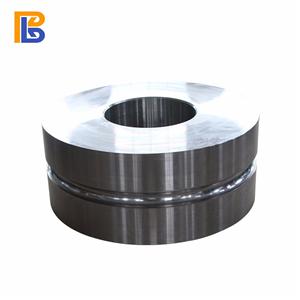

Forged Round Gear Blanks

Boberry provides Forged Round Gear Blanks products and service with quick delivery, high quality and competitive prices.

Email Details

Boberry produces Forged Round Gear Blanks by taking material flexibility, lower volume requirements, and final machining costs into consideration.

Certification: ISO9001, PED ,SGS etc. Material Report for Forged Round Gear Blanks: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report -

Hot Forged Gear Blanks For Transmission

Our produced Hot Forged Gear Blanks For Transmission take material flexibility, lower volume requirements, and final machining costs into consideration.

Email Details

Boberry improves mechanical properties and metallurgical soundness from the open die forging process, according to customer's technical drawings. Hot Forged Gear Blanks For Transmission Main material covers carbon steel, alloy steel, stainless steel and nickel alloys etc.

Boberry provides Hot Forged Gear Blanks For Transmission and service with quick delivery, high quality and competitive prices. -

Forged Gear Wheels

In order to make forging of Forged Gear Wheels, we have well equipped hammers and hydraulic presses.

Email Details

Our Forged Gear Wheels can be in the annealed, normalized, hardening and tempering as per the requirement of the clients.

Boberry can do rough or final machined of Forged Gear Wheels as per the drawing of the clients. -

Gear Industry Forged Parts

Boberry is able to produce Gear Industry Forged Parts by forging (open forging and die forging) and machining, turning, milling, grinding, boring, drilling, design and programming, and customized service.

Email Details

Boberry additional services to improve the quality and value of Gear Industry Forged Parts includes: Quench-and-Temper Heat Treating, Rough Turning, Ultrasonic Testing, Mechanical Testing and etc.

Certification: ISO9001, PED ,SGS etc. Material Report for Gear Industry Forged Parts: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report. -

Worm Gears

Boberry forged worm gears have wide use in many industries, such as

Email Details

in high-pressure triplex piston and plunger pumps,Mud pump,Fracturing Pump.

in in Cement industry and sugar industry,paper mills.off-highway.

in Drilling and Well Building, pipelines and refineries

in concrete mills and mixers

in processing units,mechanical equipment.

in mechanical presses,high speed presses,eccentric presses

in mining Machinery,such as jaw crusher, cone crusher and so on. -

Forged Parts Solution

Forged Parts Solution Standards: GB, JIS, AISI, SAE, ASTM/ASME, EN, DIN, GOST

Email Details

Main export market in Europe: such as Germany, Denmark, Austria, Czech Republic, Sweden and Turkey etc.

Forged Parts Solution Service: Custom OEM/ODM metal parts processing, Whole Product assembly, 2D & 3D drawings design, International Delivery Logistics, Service before & after sales etc.