Hot Forgings

-

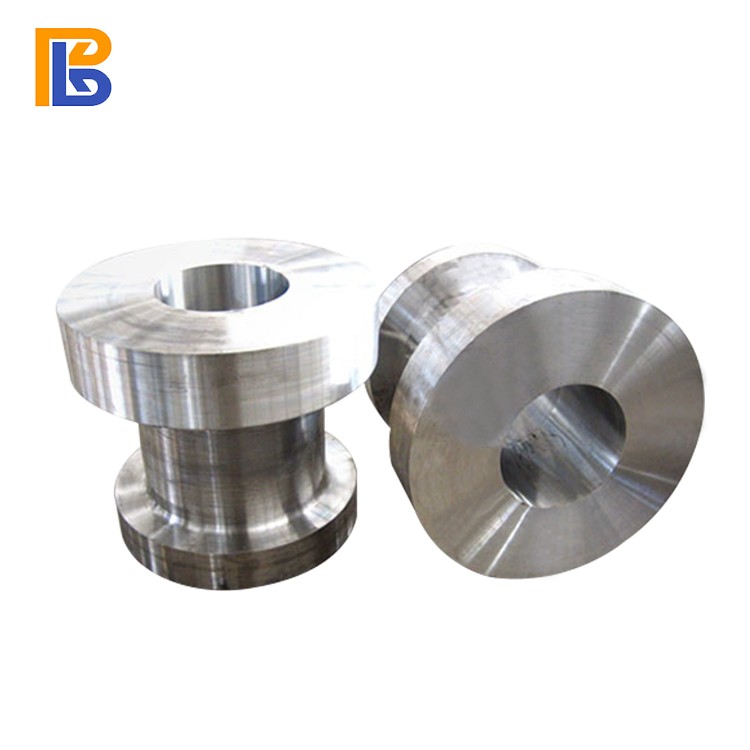

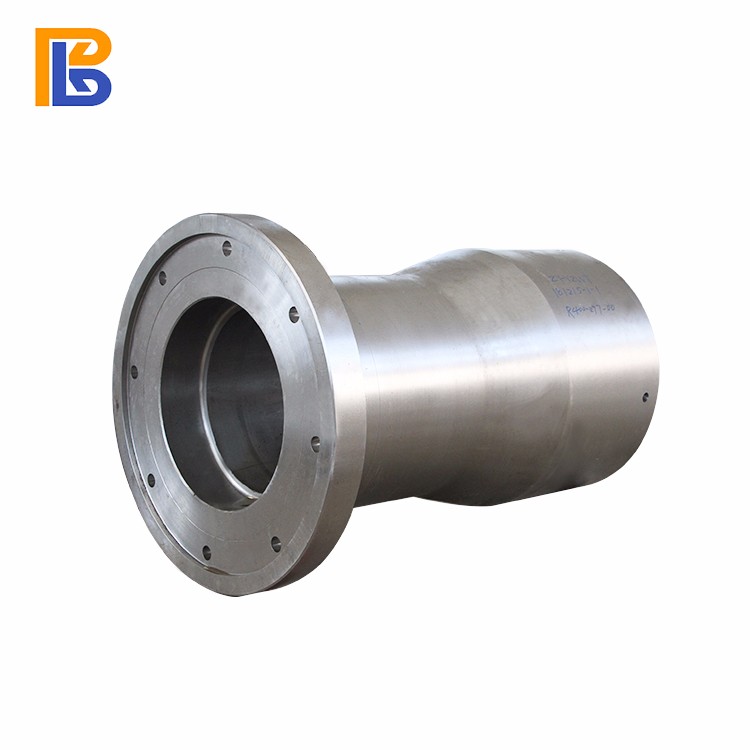

Subsea Forged Wellhead

Subsea forged wellhead parts include tubing heads, casing head,tubing head spool etc.

Email Details

Subsea Forged Wellhead Package: standrad export packaging, according to the requirements of your packaging.

Certification: ISO9001, PED ,SGS etc. Material Report for Subsea Forged Wellhead: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report. -

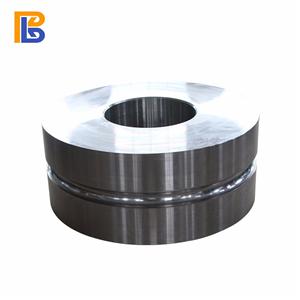

Filter And Valve Parts

Filter and valve parts are produced through forging for different kinds of shapes.

Email Details

Medium: water, oil, steam, liquefied gas.

Filter And Valve Parts Quality Assured: Strictly according to International standard ASTM & BS & EN & JIS, with System ISO certification

Filter And Valve Parts Good Service: supplied professional technical guide, free of charge at anytime. -

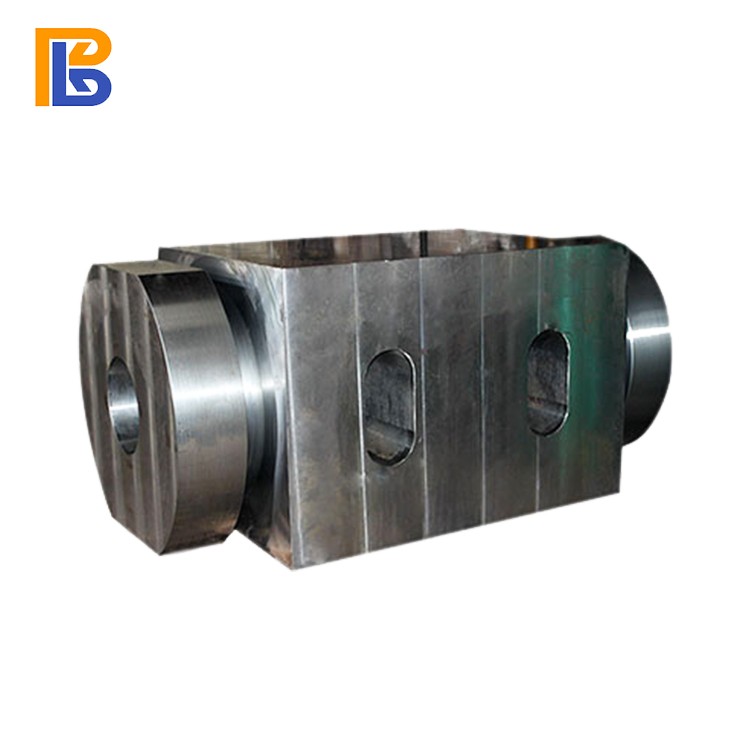

Forged Valve Bodies For Oil And Gas

Boberry produces forged valves for marine equipments, and we can produce valve bodies based on your forging drawing.

Email Details

All products flow are our manufacture bases, so we can guarantee the quality of our products. We have a professional after-sales service for Forged Valve Bodies For Oil And Gas.

Certification: ISO9001, PED ,SGS etc. Material Report for Forged Valve Bodies For Oil And Gas: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report. -

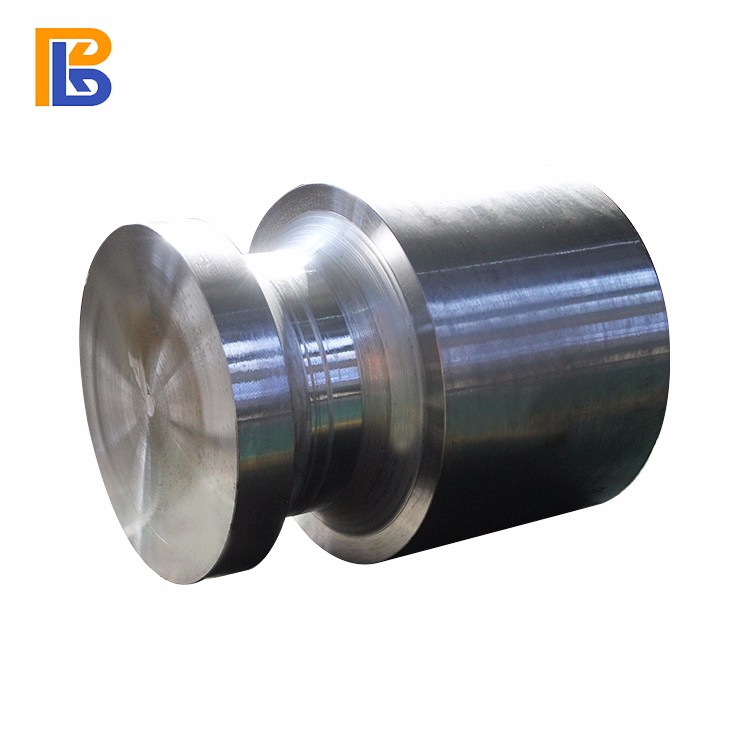

Free Forgings

Free forgings are produced based on your forging drawing. Free forgings include different kinds of shapes.

Email Details

Free Forgings Steel Treatment: Forging, Q+T(Quenching+Tempering), Solution treatment, Heat treatment.

Free Forgings Machining Service: Rough machining,Precision machining,Milling,Rolling,Hole Drilling,Stamping -

Engineering Forgings

Engineering forgings: construction machinery parts, oilfield petroleum parts, engine parts, marine parts, spare parts for mining machinery, coal mine drill, forklift, agricultural machinery, railway and train, excavator, hydraulic field parts, shipbuilding parts, pump spare parts, industrial machines, roller press.

Email Details -

Hot

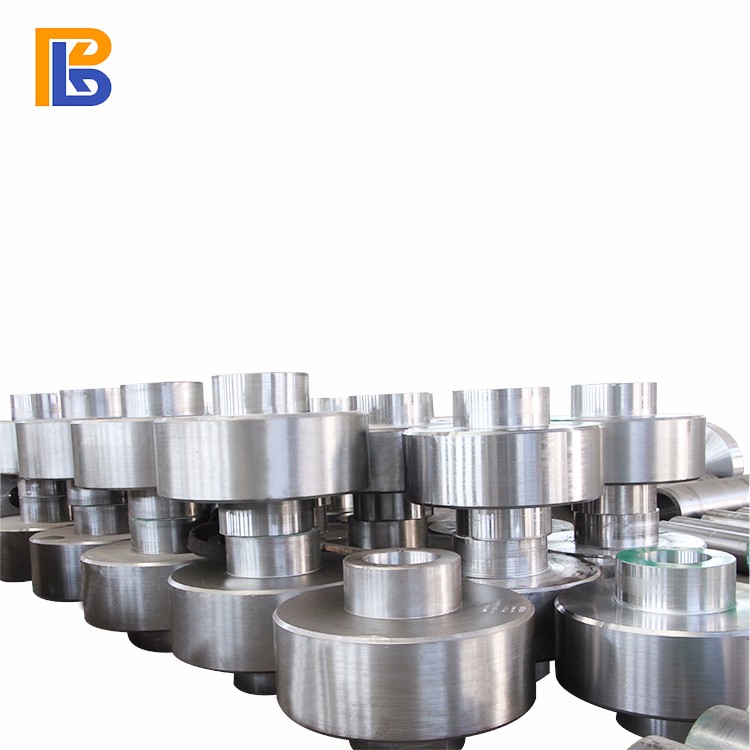

Semi-finished Forging Parts

Boberry's additional services to improve the quality and value of Semi-finished Forging Parts includes: Quench-and-Temper Heat Treating, Rough Turning, Ultrasonic Testing, Mechanical Testing and etc.

Email Details

Semi-finished Forging Parts Process: Raw material inspection →Cutting→ inspection → Preheat → forging → heat treatment → inspection → rough machining → NDT →Testing → finishing machining →NDT →inspection → packing→ Delivery. -

Hot

Complex Shape Forged Parts

Complex Shape Forged Parts Served industry for example: in Machinery, Metalworking, Power Generation, Pulp & Paper Processing and Food Processing etc.

Email Details

Certification: ISO9001, PED ,SGS etc. Material Report for Complex Shape Forged Parts: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report.

Boberry has Complex Shape Forged Parts production ability for forging (open forging and die forging) and machining, turning, milling, grinding, boring, drilling, design and programming, and customized service. -

Customized Forged Parts

Boberry has the ability in providing forged solutions for complex shapes, to create custom forged shapes for a variety of industries. We produce complex forged parts with dimensional uniformity, according to customer's drawings.

Email Details

Customized Forged Parts' raw material covers carbon steel, alloy steel, stainless steel and nickel alloys etc. -

17-4PH Special Material Forged Products

Boberry produces 17-4PH forging parts. 17-4 PH stainless steel is capable of attaining a wide range of strength and toughness properties depending on the precipitation or aging temperature used in hardening.

Email Details

17-4PH Special Material Forged Products' high strength, good corrosion resistance and toughness in both base metals and welds gives designers opportunities to add reliability to their products while simplifying fabrication and often reducing costs.