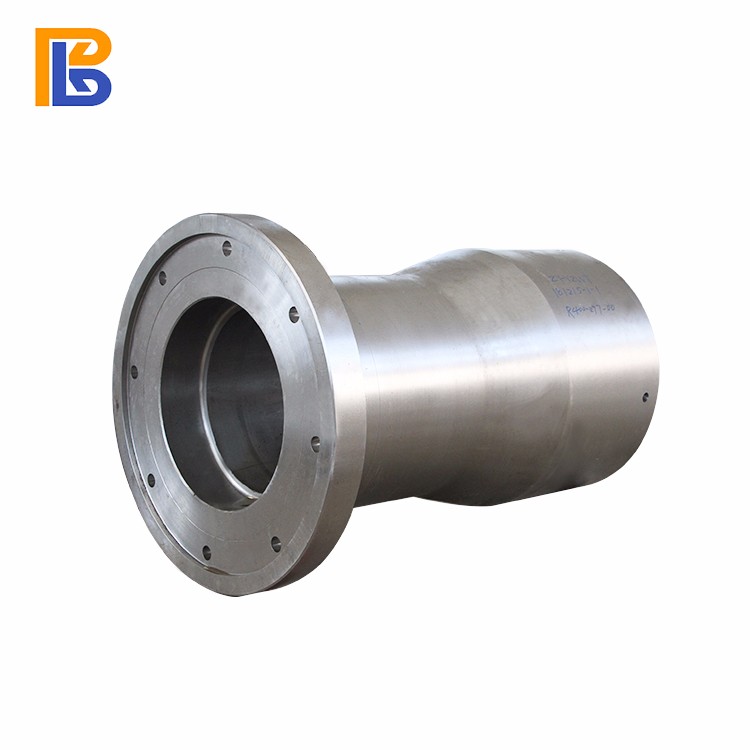

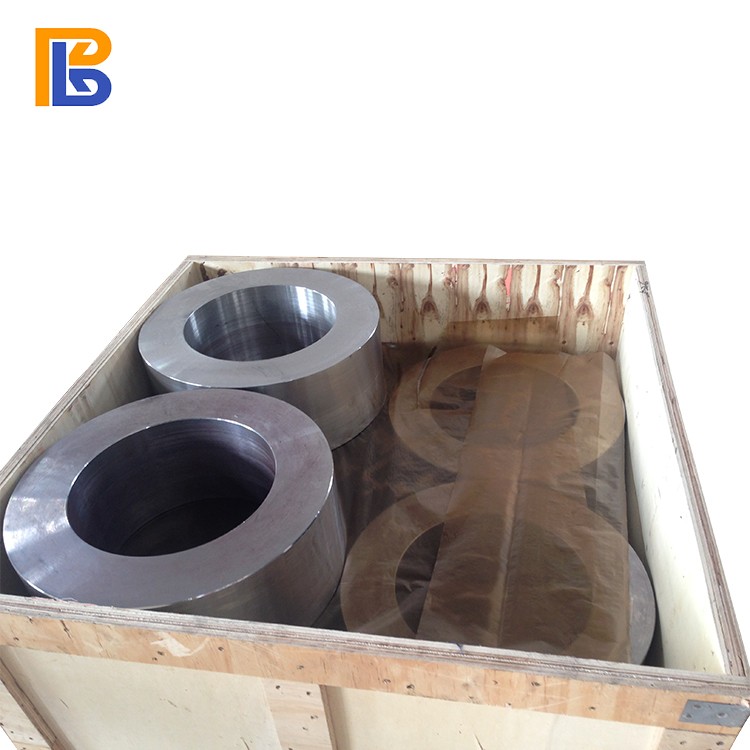

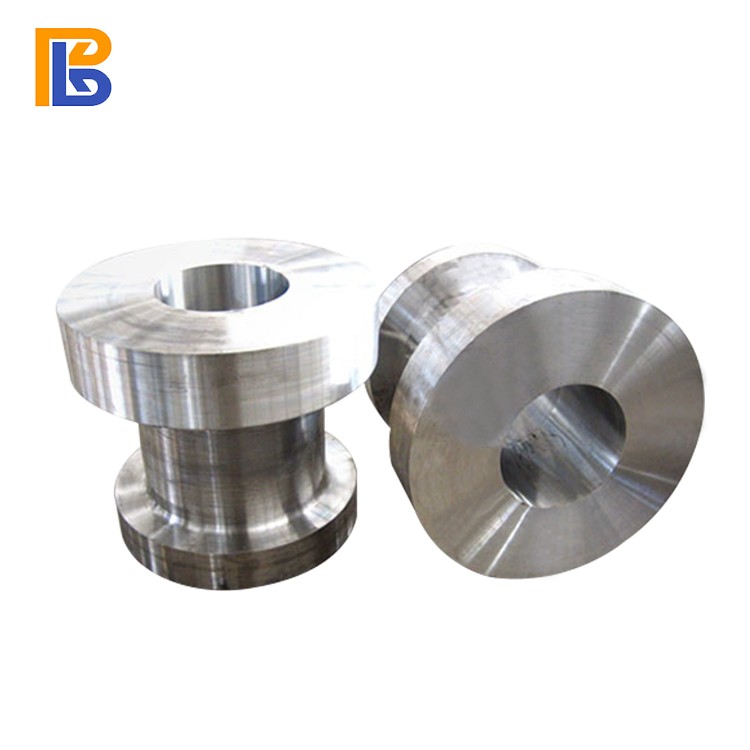

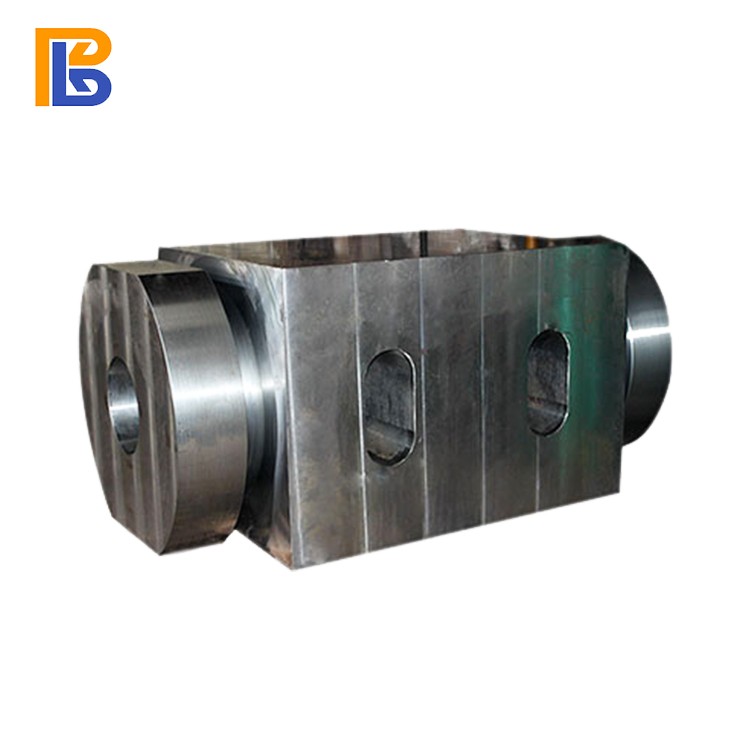

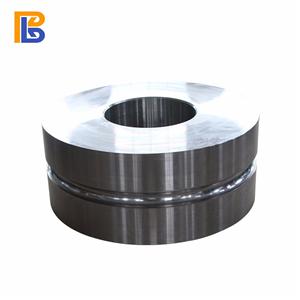

Customized Forged Parts

- BOBERRY

- China

- 15-30 days for urgent orders, 30-45 days normally

- 500-1000 Tons/month

Boberry has the ability in providing forged solutions for complex shapes, to create custom forged shapes for a variety of industries. We produce complex forged parts with dimensional uniformity, according to customer's drawings.

Customized Forged Parts' raw material covers carbon steel, alloy steel, stainless steel and nickel alloys etc.

Customized Forged Parts' Process: Raw material inspection →Cutting→ inspection → Preheat → forging → heat treatment → inspection → rough machining → NDT →Testing → finishing machining →NDT →inspection → packing→ Delivery.

Smelting facilities for Customized Forged Parts:

30T Electric furnaces

30T/60T LF refining furnaces

30T VD/VOD furnace

60T VC furnace

Special smelting equipment( 5T VIM, 200kg VIM, 3T/5T IGESR)

100T large scaled electroslag furnace

Forging facilities for Customized Forged Parts:

6300T free hydraulic pressure machine

3150T free hydraulic pressure machine

2000T free hydraulic pressure machine

5T electro-hydraulic hammer

3T electro-hydraulic hammer

2T electro-hydraulic hammer

1T electro-hydraulic hammer

750kg electro-hydraulic hammer

560kg electro-hydraulic hammer

Machining facilities for Customized Forged Parts:

CNC machines with maximum loading capacity 32 tons

General heavy-duty machines with maximum loading capacity 70 tons.

Gantry milling machines

Deep hole boring machines.

Testing facilities for Customized Forged Parts:

Spectrum test machine

Non-destructive test device

Mechanical properties test machine

Metallographic test equipments

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more