Lost Wax Castings

- BBR

- JIANGSU

- 45DAYS

- 100-150Tons/month

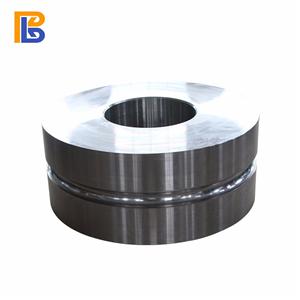

There are the excellent high precision, well the surface smoothness for Lost Wax Castings.

Can customized according to clients' requirement.

Lost Wax Castings material can be staineless steel(eg: SS316 ,SS304), carbon steel, duplex steel,aluminium and other material.

Demensions depends on shape and weight, max 1500*1500*1500mm,

Lost Wax Castings -- 0.001kg~99kg,Sand casting -- 0.5kg~500kg

Alloy Applications

304304 is widely accepted in plate heat exchanger ,sylphon bellows, food industry ,medical,Mining,petrochemical ,construction industry , automotive industry , offshore , agriculture ,etc

304L/316L 304L can be used to weld,can bear high tempreture ,the 316L can be used to piping ,heat exchanger, food industry , chemical industry

316 it is used to paper - making industry , heat exchanger , piping line , offshore , constrution , valve ,etc.

Lost Wax Castings can be used to many area products, include: construction machinery, power machinery, automobile, agricaltural machinery, mining, metallurgy, electric power, marine ,ect.

Lost Wax Castings are suitable to produce many kinds of complex construction and alloy material,and the products there is high dimension tolerance ,the surface quantity is more better than other casting.

304L/316L 304L can be used to weld,can bear high tempreture ,the 316L can be used to piping ,heat exchanger, food industry ,chemical industry

316 it is used to paper - making industry , heat exchanger , piping line , offshore , constrution , valve ,etc.

Due to easy modular,so can make many area arts and crafts.

Lost Wax Castings regular materials: 35SiMn、40Cr、25CrMo、30CrMo(4130)、35CrMo、42CrMo(4140)、50CrMo、12Cr1MoV、25Cr2MoVA、38CrMoAI、etc

| TYPE | Chemical composition(%) | ||||||||

| C | Si | Mn | S | P | Cr | Ni | Mo | Cu | |

| ZG40Mn | 0.3-0.45 | 0.30-0.45 | 1.20-1.50 | ≦0.030 | |||||

| ZO40Mn2 | 0.35-0.45 | 0.20-0.40 | 1.60-1.80 | ≦0.030 | |||||

| ZG50Mn2 | 0.45-0.55 | 0.20-0.40 | 1.50-1.80 | ≦0.030 | |||||

| ZG20SiMn | ≦0.023 | ≦0.60 | 1.00-1.50 | ≦0.025 | ≦0.30 | ≦0.40 | ≦0.15 | ||

| ZG35SiMn | 0.30-0.40 | 0.60-0.80 | 1.10-1.40 | ≦0.030 | |||||

| ZG35SiMnMo | 0.32-0.40 | 1.10-1.40 | 1.10-1.40 | ≦0.030 | ≦0.30 | ≦0.30 | 0.20-0.30 | ≦0.30 | |

| ZC35CrMnSi | 0.30-0.40 | 0.50-0.75 | 0.90-1.20 | ≦0.030 | 0.50-0.80 | ||||

| ZG20MnMo | 0.17-0.23 | 0.20-0.40 | 1.10-1.40 | ≦0.030 | ≦0.30 | ≦0.30 | 0.20-0.35 | ≦0.30 | |

| ZG55CrMnMo | 0.50-0.60 | 0.25-0.60 | 1.20-1.60 | ≦0.030 | 0.60-0.90 | ≦0.30 | 0.20-0.30 | ≦0.30 | |

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more