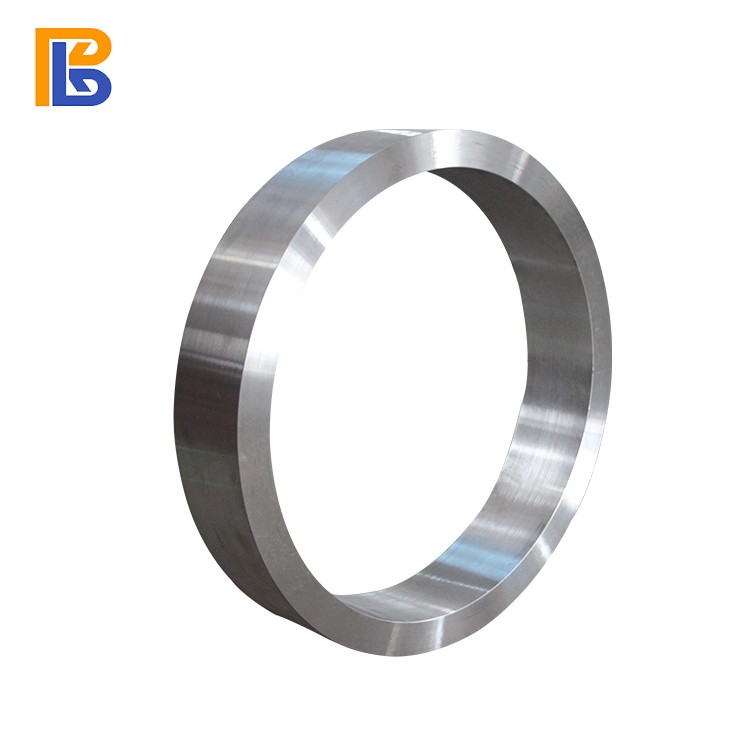

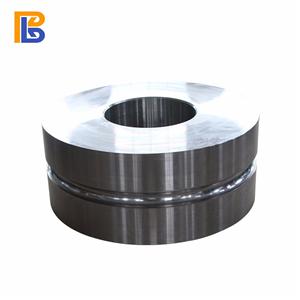

Steel Forged Rollers

- BOBERRY

- China

- 30-45 Days

- 500-1000 Tons/month

We are specialized in manufacturing different type of Steel Forged Rollers according to customers' requested, with more than 10 years experience.

Our ring rolling Machining Tolerance: -/+ 0.01mm,

Our ring rolling Machining Roughness: Max. Ra 0.4

We have matured manufacturing technology and well exporting experience to overseas, so we can help you handle the difficult matters and help you save the manpower and time cost.

Steel Forged Rollers

Gerneral Products Introduction

Our forged rollers Capability:

Max Diameter: 8000 MM

Max Length: 1200 MM

Max Weight: 7000 KGS

| Name | Steel Forged Rollers |

| Materials | Steel, Carton steel, Alloy steel and stainless steel, etc |

| Dimension | As customer required |

| Process | Forging+Rough machining+Heat treatment+Final machining+Inspection |

| Machining | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc |

| Heat Treatment | Annealing Normalizing Quenching&Tempering Hardening |

| Nondetective Examation | Magnetic particle test Penetration test Ultrasonic test Radio graphic test And, others as customers requirements |

| Application | Marine, weapons, petrochemical industry, mines, nuclear power, thermal power, hydropower |

| Remarks | As customers request |

| Package | Seaworthy Plywood Cases or pallet or as per customers requirement |

| Delivery time | 15-35 days |

| Markets | Europe, US, North America and Asia |

![]() Quality Control

Quality Control

For products of steel forged rollers, our forging, heat trreatment,machining and related process equipments status are according to manufacturing standards and the specification of ISO9001 quality management system.

The quality of products are comply with the Germany Pressure element standard production specification PED and AD2000, or comply with customers customized requirements.

Meanwhile, we can offer you mill test report with 3.1 or 3.2 by third-party inspection mechanism.

Other Information

1,Shipment: By Sea (recommend, save cost for forgoing parts)

By Air (fast, but expensive)

2, Payment terms: 30% deposit, the balance aganist with the copy of B/L

100% L/C at sight

3, Delivery terms: FOB, CIF, CNF

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more